Zinc coatings – acid or alkaline process

For decades, zinc coating has been established and used globally as a good means of protecting steel in environments subject to mild to moderate corrosion.

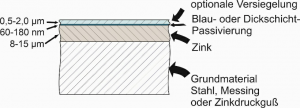

During zinc electroplating, a layer of usually between 8 and 15 micrometres of zinc is deposited at an electrolyte temperature of approx. 30°C. In the acid zinc process, a thicker layer is often used.

To increase the corrosion protection, various passivation layers are then applied to the zinc: e.g. the slightly iridescent thick-layer passivation with a thickness of approx. 140 to 180 nanometres or blue chromate passivation, with a thickness of around 40-60 nanometres.

The components can then be provided with a silicate-based or polymer-containing sealer to further improve scratch resistance and corrosion protection.

This results in a long-lasting coating that delivers precisely tailored corrosion protection at a reasonable price.

Thanks to the good distribution of layer thickness, depending on the process, features such as threads are no problem.

Corrosion protection standards:

- Up to 168 h without zinc corrosion

- up to 360 h without base material corrosion in a neutral salt spray test

Examples:

- DIN 19598 – Fe//Zn8-15/Cn//T2

- DIN 19598 – Fe//Zn8-15/An//T0

- Daimler Benz: DBL 8451.16

- MAN: 183-3 B13

- Continental: PP212

- VW: 13750 r342/r343

- Parker: FC-F01

- Liebherr: LN 252-7